Get in touch!

Alternatively, you can contact us like this:

If you're not sure which product you need, try our Quick Product Finder

Technical Centre

Digital Power FAQ

Select question from the list below.

-

What’s all this stuff about 'Digital Power'?

It seems that every 2-3 weeks an article or news announcement about “Digital Power” appears in electronic design periodicals or online news links. In fact, one industry newsletter seems to be having a love affair with digital power, as it mentions it in just about every issue.

So what is all this fuss about Digital Power and what is it anyway? Well, the simple answer is that there are two basic types of digital power. These are Digital Control (used internal to the power devices) and Digital Power Management (provides external control and communications between power devices and a master controller).

-

What is Digital Control?

The majority of switched mode AC-DC and DC-DC power supplies/converters use analogue techniques to regulate/control the output voltage, current, and power factor correction circuits, etc. The closest that most of these devices come to looking a bit digital (On/Off states) in nature is by employing Pulse Width Modulation (PWM) in their switching regulator circuits; but even that is a bit of a stretch.

In recent years, new integrated circuits (ICs) have been developed that can replace “analogue” control ICs and discrete circuits, which are used extensively in all power devices, with those that are, at least in part, “digital” in nature. These internal ICs and circuits perform such control functions as: voltage regulation (VR), power factor correction (PFC), pulse width modulation (PWM) control, internal monitoring/alarms, and external communications.

The advantage of these digital ICs is that they can be programmed by engineers with digital or analogue electronics training. And, since the Universities are pumping out more digital (e.g., computer science) than analogue engineers these days, these digital ICs are becoming attractive. However, at present the cost of these digital ICs (along with NRE for the equipment needed to program the devices) is still higher than for the mature analogue ICs. Nonetheless, some predict that these IC costs will become equal within the next 12 months or so. A potential disadvantage of these digital ICs is that, by their nature, they require a high speed clock to operate, which can add to the radiated and conducted noise coming from the power supply or converter. However, advanced functions such as fault diagnostics/prevention and improved power efficiencies are among the promises of the new digital control ICs.

-

What is Digital Power Management?

Digital Power Management (DPM) involves the external control and communications between power supplies (or converters) and a master controller. Currently, many analogue-based power solutions already have the ability to communicate with an external computer or controller via digital communications links (e.g., RS232, RS485, GPIB, or I2C bus).

Newer DPM control and communications formats have evolved that are designed to operate with the new digitally-controlled power devices. These include DPM technologies such as PMBus (Power Management Bus) and Z-One. Sadly, these technologies are not compatible or interchangeable. In fact, currently there are lawsuits between the backers of both of these technologies.

If I were a potential user of these Digital Power Management schemes, I would stay clear of them until the lawsuits are settled (expected to occur within the next 12 months), rather than find out later that the cost of these DPM ICs or controllers have substantially increased due to royalties that must now be paid to the company that won the lawsuit.

The potential advantages of the DPM and digital power technologies in general, include enhanced bidirectional communications, fault diagnostics, remote programming of the linked power supplies/converters, automatic compensation of dynamic input and output load changes, and overall improvements in efficiencies that relate to green-power.

-

In Summary

Although "Digital Power" is a popular buzzword these days, especially by those companies who have developed or adopted the technologies, the bottom line will always be: "What do I get for my money?" At present, there are hardly any power supply or converter applications that "must have" digital power when compared to the many lower cost and field-proven analogue solutions that exist.

For example, during their new power-product design and development process, TDK-Lambda has designed in-parallel devices that employed both analogue along with those that use digital control ICs and technologies. In all cases, the final decision on which technology ultimately goes into production has been based on comparative price/performance factors; which is the dominant decision factor for their customers.

When the time comes that digital power products offer the same or better performance and reliability, along with the ”needed features”, at the same or lower price as analogue-based products, that is when Digital Power will become the winning technology. Realistically, someday digital power will provide a price/performance advantage over purely analogue power devices. Who knows for sure when that time will come.

-

What is Fold-Back Current Limiting?

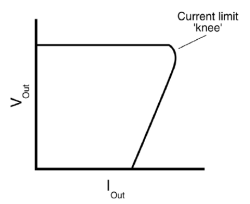

When this method is employed if an overload condition exists, the output voltage and current reduce to safe levels. As can be seen from the following curve, should an overload occur the supply will provide current up its current limit point (aka 'knee'), and then the output current will fold-back to a lower value as the output voltage reduces towards zero.

This technique is employed in linear power supplies because it reduces the strain on the supply’s internal power devices to minimum. One drawback of fold-back current limiting is that if the supply turns on into a heavy capacitive load, it could latch-up at a reduced current before reaching its full output voltage. Depending upon the design, recovery from a fold-back current limit condition can be automatic, or after a built-in time delay when the overload condition is removed.

Fold-Back Current Limiting

-

What is Fold-Forward Current Limiting?

In this method, when an overload is sensed the output voltage reduces towards zero, but the current increases. When driving motors, pumps, or highly capacitive loads, employing a fold-forward current feature can help overcome the electrical inertia of these loads. Recovery from a fold-forward current limiting situation is usually automatic when the overload is removed.

Fold-Forward Current Limiting

-

What is Constant Current Limiting?

In this method, should an overload occur, the output current stays at its limit point and the output voltage reduces towards zero in a somewhat linear fashion. This technique is used in many switch mode power supply designs. Typically, the supply will automatically return to its normal output voltage when the overload condition is no longer present.

Constant Current Limiting

-

What is Current Limit Shutdown?

In some power supply designs, when an overload occurs the power supply will begin to go into a constant-current limit mode, but when the output reaches a preset reduced voltage, the supply will shutdown. Recovery from this condition can be automatic or require recycling of the input power.

-

What is Hiccup Mode Current Limiting?

Some low power supplies have what is termed a hiccup current-limit feature. As the name implies, if a current limit is sensed, the supply will reduce its output voltage to zero and then, after a short time, it will attempt to provide its normal voltage. These On-Off attempts at operation are referred to as a hiccup-mode. Should the overload condition be removed, the supply will again operate normally.

-

What are Peak-Current Power Supplies?

It should be mentioned that some power supplies are designed specifically to provide large peak-currents, which can range from 200 to 300% of the maximum current rating for a short duration, without going into a current-limit condition. These are especially useful when powering loads that include electric motors such as computer hard drives, fans, actuators, pumps, etc. When using this type of power supply it is important to limit the “average power” that is delivered to load. More information about peak-current-rated supplies will be provided in a separate article.

If you can't find what you're looking for then feel free to get in touch