U kunt ook op de volgende manier contact met ons opnemen:

TDK-Lambda Nieuws

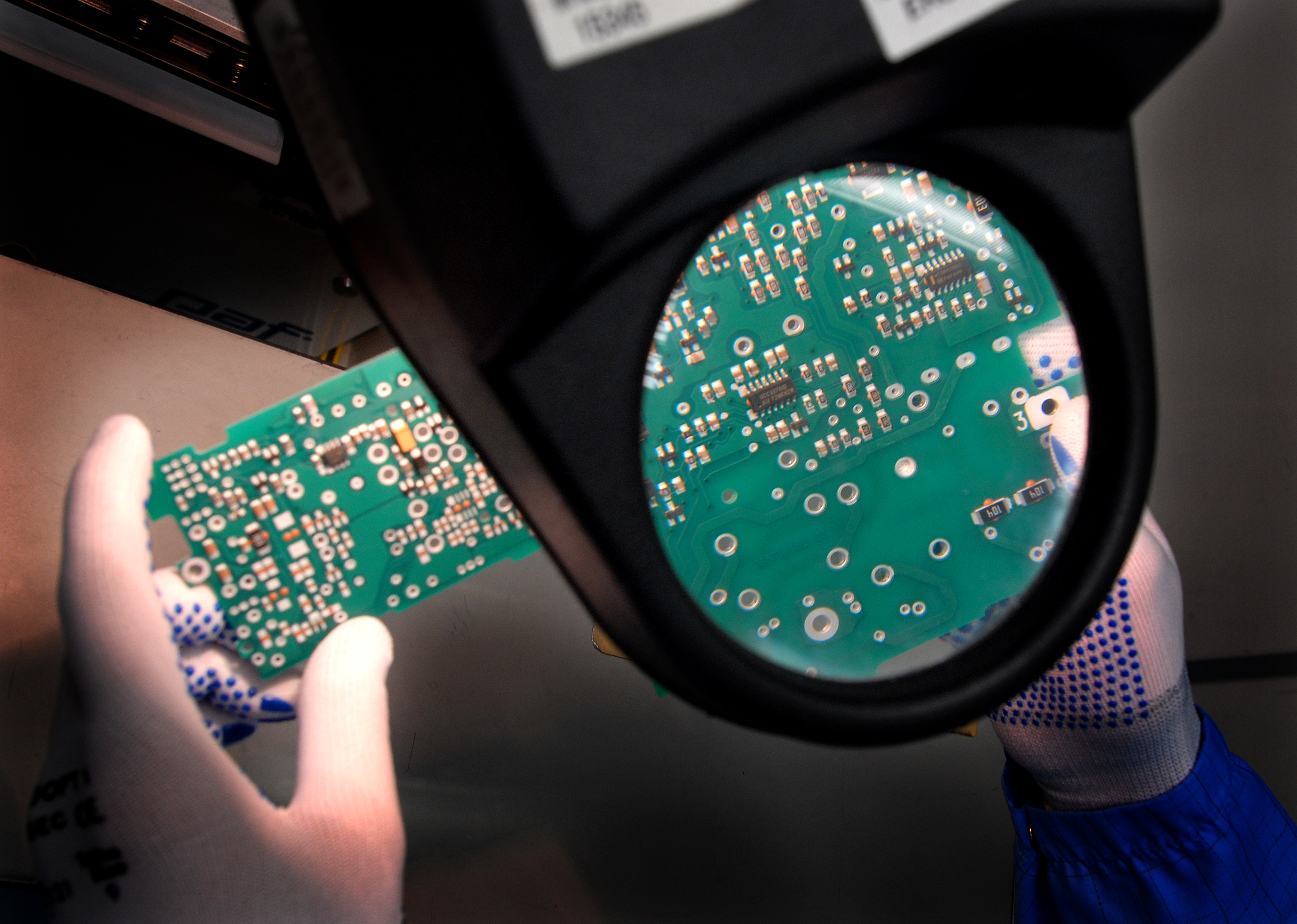

Five Green Belts Awarded for Lean Six-Sigma at TDK-Lambda

Geplaatst : 19 Feb 2009

TDK-Lambda is delighted to announce that five more members of its production team have attained Green Belt status in Lean Six-Sigma techniques. Underpinning its commitment to the continued investment in skills development, one of the projects undertaken during the Lean Six-Sigma green belt programme promises to net TDK-Lambda substantial energy savings.

Already impressed by the achievements these new green belt holders have made Phil Scotcher, General Manager of TDK-Lambda UK (Configurable Products), reveals: “Through the one project alone, we are hoping to achieve considerable savings in reduced electricity consumption… good for the company and for the environment!”

A combination of the Lean Manufacturing and Six Sigma models, the Lean Six Sigma business improvement model uncovers where quality improvements, additional efficiencies and cost savings might lie. Speaking about the programme the engineers followed, Jane Worley, TDK-Lambda’s Training Officer, says: “The South West Manufacturing Advisory Service (SWMAS) runs this comprehensive programme. It consists of three sets of three day sessions detailing Lean Six-Sigma tools and techniques, followed by three project review days and a final certification day.”

The total programme takes about six months to complete, allowing lots of time for project work between each monthly session. New green belt holder Jeff Bowden, an SMT and sub-assembly test process support engineer working in the Manufacturing Engineering Department (MED), said “Throughout the programme we were reminded time after time about the importance of obtaining the right data about a process, handling it in such a way as to generate the most relevant information, and then acting on this information in the correct fashion.”

Lean Six-Sigma does not guarantee success in business, but its application does offer a blue-print for not repeating the same mistakes. Throughout the training period, the five trainees were engaged in running two TDK-Lambda projects with the aim of improving control and reducing error margins in the manufacturing process.

TDK-Lambda has a number of experienced Six Sigma Black Belts within the UK facility, one of whom is Senior Quality Engineer, Carl Besford. He supervised the in-house projects: “The green belt programme has shown that dividends can be reaped from collecting data in relation to a process, and acting on it in an appropriate way. Within a manufacturing process, any movement away from a ‘do it the way it has always been done’ workplace ethic, towards a thought-through systemic review and renewal of process, can only serve to improve efficiency and productivity. Cutting unnecessary costs whilst, at the same time, increasing output and improving quality can only lead to benefits for the company that achieves them.”

As yet, TDK-Lambda has invoked Lean Six-Sigma whenever it’s deemed relevant such as on critical process validation. However, this technique is also applicable to non-production areas and it is envisaged that it will permeate other areas of the business.